Transforming Ideas into Reality: The Role of Rapid Prototyping Manufacturing Suppliers

In modern manufacturing and product development, the importance of rapid prototyping cannot be overstated. As industries seek to innovate and bring products to market faster than ever before, the role of rapid prototyping manufacturing suppliers becomes crucial. These suppliers enable businesses, including metal fabricators, to convert ideas into tangible products swiftly and accurately.

What is Rapid Prototyping?

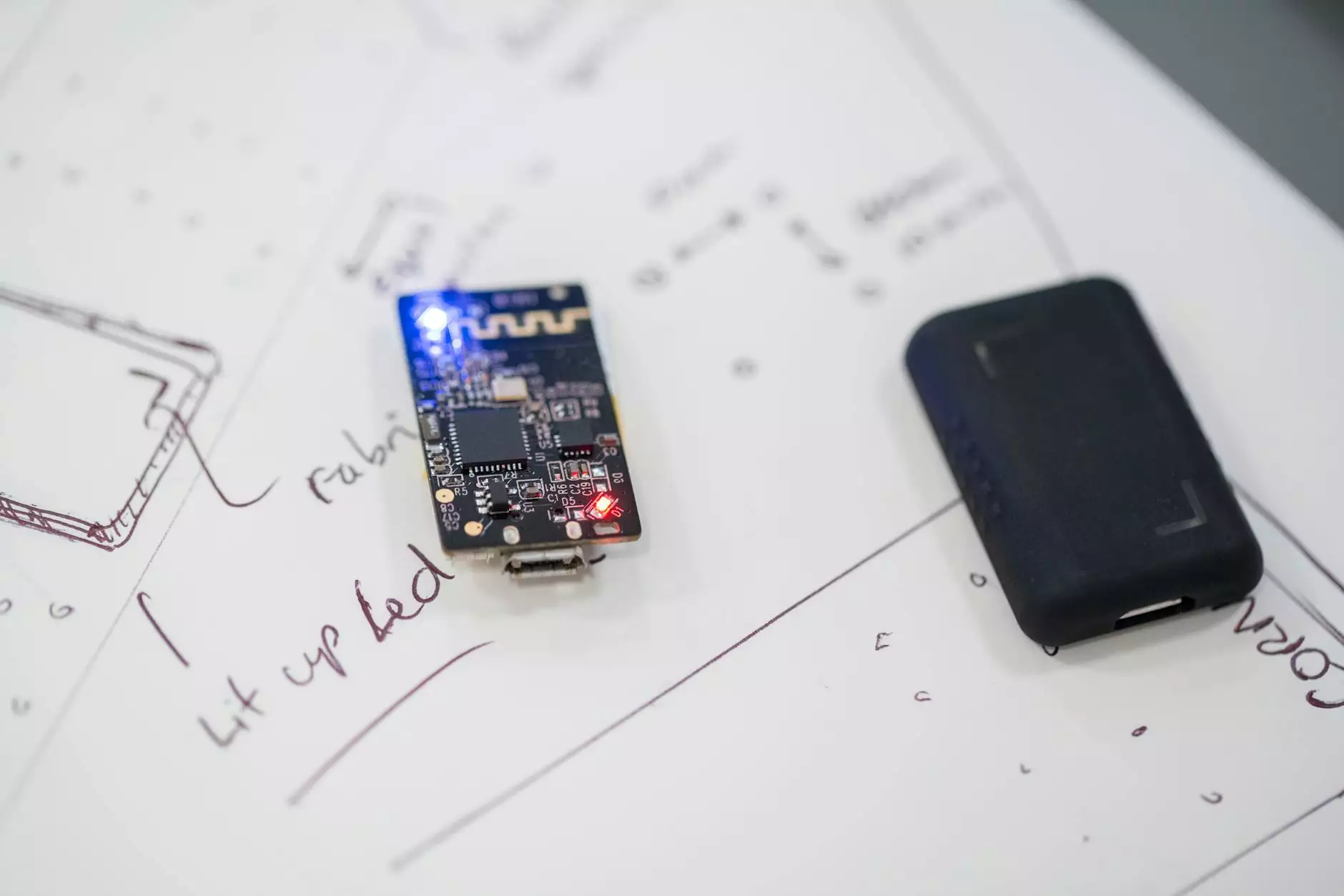

Rapid prototyping is a sophisticated technique that allows designers and engineers to create physical models of their concepts quickly. Utilizing advanced technologies such as 3D printing, CNC machining, and laser cutting, rapid prototyping helps streamline the development process, enabling companies to test, iterate, and refine their designs efficiently.

Key Benefits of Rapid Prototyping

- Speed: Rapid prototyping significantly reduces the time taken to develop a prototype, allowing for quick iterations.

- Cost-Effectiveness: Early detection of design flaws through prototyping saves money on large production runs.

- Enhanced Communication: Physical prototypes facilitate clearer communication among stakeholders and team members.

- Increased Innovation: Rapid prototyping encourages experimentation, leading to innovative solutions.

The Importance of a Reliable Rapid Prototyping Manufacturing Supplier

Choosing the right rapid prototyping manufacturing supplier is imperative for success in product development. A reliable supplier not only provides high-quality prototypes but also contributes valuable expertise throughout the design process.

What to Look for in a Supplier

When selecting a rapid prototyping partner, several factors should be considered:

- Technology and Capabilities: Ensure the supplier uses the latest technologies that align with your specific prototyping needs.

- Experience and Expertise: Look for a supplier with a proven track record in your industry and knowledge of your specific applications.

- Material Variety: A good supplier should offer a range of materials to choose from, allowing you to test different functionalities.

- Customer Support: Superior customer service is vital for effective communication and problem resolution.

- Turnaround Time: Assess the supplier’s ability to meet your project deadlines without compromising quality.

How Rapid Prototyping Benefits Metal Fabricators

For metal fabricators, rapid prototyping serves as a game-changer. The ability to create prototypes quickly can significantly enhance the manufacturing process and product offerings.

Applications of Rapid Prototyping in Metal Fabrication

- Design Validation: Fabricators can create and test metal components before moving into full-scale production.

- Complex Geometries: Prototyping allows for the exploration of intricate designs that may be challenging to fabricate traditionally.

- Rapid Tooling: Prototyping can facilitate the rapid creation of tooling fixtures and molds necessary for production.

- Iterative Testing: Frequent testing and modification lead to improved product quality and performance.

Case Studies: Successful Prototyping in Action

Let’s explore a few examples that showcase the transformative power of working with reliable rapid prototyping manufacturing suppliers in the metal fabrication sector.

Case Study 1: Aerospace Components

A leading aerospace company faced challenges in developing a new lightweight component for its aircraft. By partnering with a rapid prototyping manufacturing supplier, they were able to produce and test multiple iterations of their design. This collaboration resulted in a more efficient manufacturing process and a product that exceeded performance expectations.

Case Study 2: Automotive Industry Innovations

In the automotive industry, a manufacturer aimed to enhance its vehicle design. By utilizing rapid prototyping technologies, they developed a prototype of a new dashboard design that incorporated cutting-edge technology and user-friendly features. This process allowed them to gather user feedback early on, leading to better customer satisfaction upon launch.

Future Trends in Rapid Prototyping

The landscape of rapid prototyping is continually evolving, influenced by innovations in technology and shifts in industry demands.

Emerging Technologies

Technologies such as additive manufacturing, AI-integrated design tools, and advanced materials are increasingly becoming part of the prototyping ecosystem. These developments are expected to enhance the speed and functionality of prototypes, allowing for even more complex designs.

Sustainability Considerations

As sustainability becomes a greater concern across industries, rapid prototyping can play a crucial role. Suppliers are now focusing on eco-friendly materials and processes that reduce waste, making prototyping not only effective but also sustainable.

Conclusion: The Path Ahead with Rapid Prototyping Manufacturing Suppliers

In conclusion, the integration of rapid prototyping manufacturing suppliers into the production and development process is proving invaluable for businesses, especially metal fabricators. Through their capabilities, these suppliers offer speed, cost savings, enhanced communication, and innovative opportunities to test and refine product designs. As industries continue to advance, partnering with these suppliers will be essential for staying competitive in a dynamic market.

By embracing rapid prototyping, companies are not just improving their product development cycles; they are also paving the way for a future of innovation, responsiveness, and sustainability that meets the evolving needs of customers and markets.

Explore the Possibilities with DeepMould.net

For companies looking to revolutionize their product development process through rapid prototyping, DeepMould.net stands out as a trusted partner. With our expertise in metal fabrication and a commitment to quality and innovation, we are uniquely positioned to help businesses unleash their potential. Connect with us today to learn how we can assist you in turning your innovative ideas into reality.